Laser Cutting

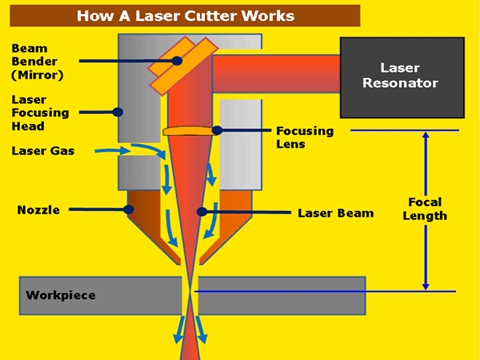

Laser cutting is a technology that uses a

laser to slice materials. While typically used for industrial manufacturing

applications, it is also starting to be used by schools, small businesses, and

hobbyists. Laser cutting works by directing the output of a high-power laser

most commonly through optics. The laser optics and CNC (computer numerical

control) are used to direct the material or the laser beam generated. A

commercial laser for cutting materials uses a motion control system to follow a

CNC or G-code of the pattern to be cut onto the material. The focused laser

beam is directed at the material, which then either melts, burns, vaporizes

away, or is blown away by a jet of gas, leaving an edge with a high-quality

surface finish.

There are three main types of lasers used in laser cutting. The CO2 laser is suited for cutting, boring, and engraving. The neodymium (Nd) and neodymium yttrium-aluminium-garnet (Nd:YAG) lasers are identical in style and differ only in application. Nd is used for boring and where high energy but low repetition are required. The Nd:YAG laser is used where very high power is needed and for boring and engraving. Both CO2and Nd/Nd:YAG lasers can be used for welding.

CO2 lasers are commonly "pumped" by passing a current through the gas mix (DC-excited) or using radio frequency energy (RF-excited). The RF method is newer and has become more popular. Since DC designs require electrodes inside the cavity, they can encounter electrode erosion and plating of electrode material on glassware and optics. Since RF resonators have external electrodes they are not prone to those problems. CO2 lasers are used for industrial cutting of many materials including titanium, stainless steel, mild steel, aluminium, plastic, wood, engineered wood, wax, fabrics, and paper. YAG lasers are primarily used for cutting and scribing metals and ceramics.